Advanced welded spot of anti-surge wire wound resistor

The wire wound resistors have been around for more than a half century, they are usually existing in high power circuit design, but are not suitable for anti-surge applications. The reason is a reliability problem of the solder joint between alloy wire and metal cap, when the wire wound resistors are produced, the joint of the welded spot and metal cap may have false welding on the welded spot. Hence, the welded spot will be easily broken when surge across it with huge energy.

Implement

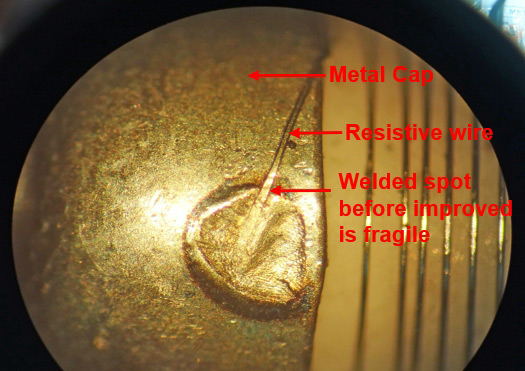

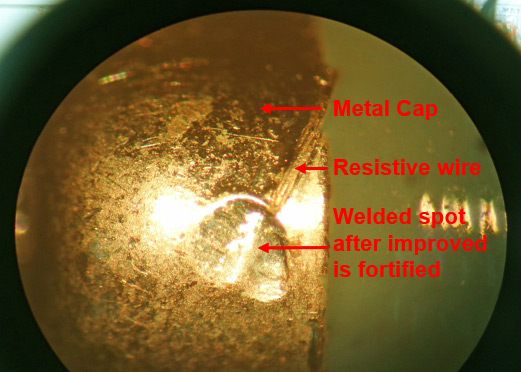

Firstohm realizes the reliability of the welded spot is a key factor to withstand surge. Therefore, we did some researches and avovid this problem. Below pictures show the original welded spot and after implementation:

Original - Traditional wire-wound resistor – Welded spot is not reliable against surge

Firstohm - Improved anti-surge welded spot

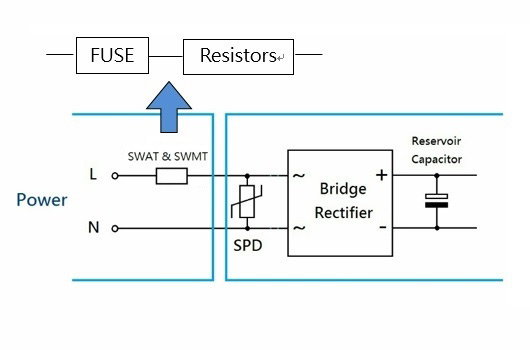

SWAT/SWMT : Anti-Surge Wire Wound Fast-Fuse (MELF) Resistor

Feature

- Granted multinational patents.

- Enhanced welded spot is reliable against surge.

- Fast-acting fuse device for high power applications.

- Advanced combined anti-surge & fast-fuse structure.

- Flameproof multi-layer coating equivalent to UL 94 V-0.

- Flameproof feature equivalent to overload test UL 1412.

- Thermal fuse to protect against overheating in electronic products.

Reference Design

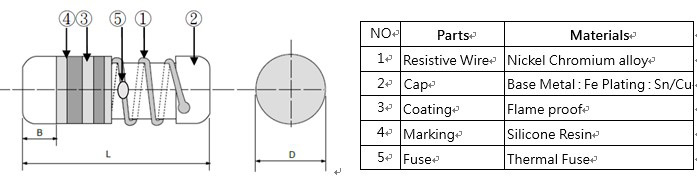

Structure

Application

- Power supply

- Charger for mobile phone

- LED Lighting

- Motor star-up protection

- Motor ignition

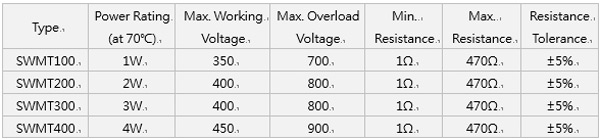

General Specification

- Files Download

Anti-Surge Wirewound Fast-Fuse Resistor

Anti-Surge Wirewound Fast-Fuse Resistor is specially design a fusible function upon wirewound resistor.

DownloadAnti-Surge Wirewound Fast-Fuse MELF Resistor

Anti-Surge Wirewound Fast-Fuse MELF Resistor is the same as SWM series but specially add fusible function.

Download